Don't have an account yet? To register>

Password set successfully

Already have an account? Go to login>

Don't have an account yet? To register>

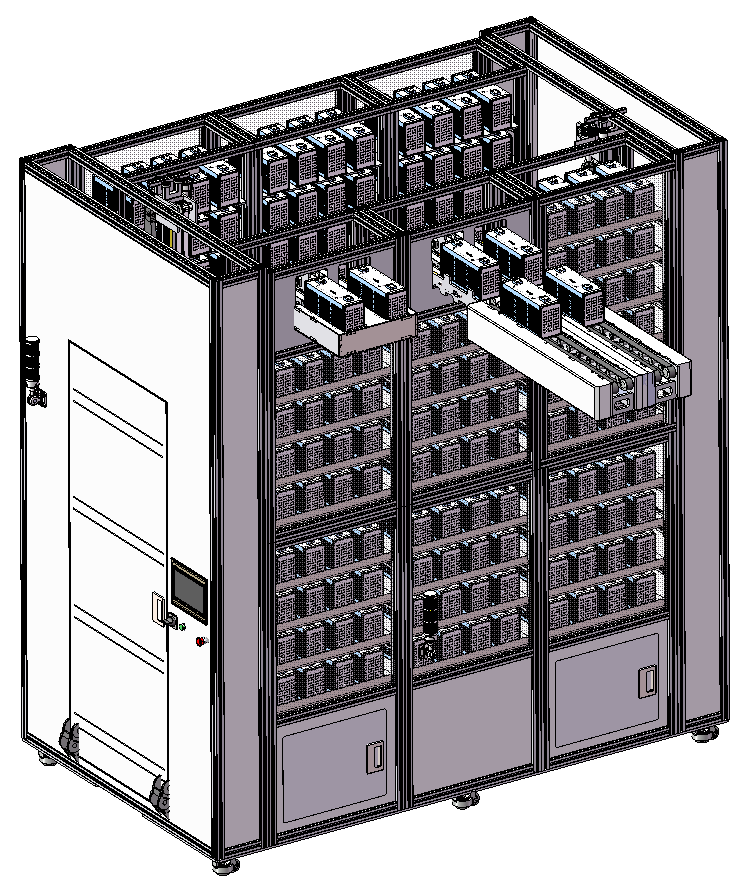

MINILOAD

Mini Load is suitable for automated storage and retrieval of MGZ standard vehicles, achieving efficient storage, precise sorting, and rapid turnover of materials through compact stackers, high-density shelves, and intelligent scheduling software.

Related products

Composite robots have integrated operational capabilities for movement, grasping, and handling, with high precision, flexibility, scalability, ease of operation, and human-machine collaboration. They can support rapid integration and landing in different scenarios, simplify complex material handling scenarios, and achieve more efficient industrial automation.

Technical highlights

- High speed cycle: The high-speed stacker crane has a fast speed, and the high-speed robotic arm has a fast cycle

- High density storage: The shelf layers are highly adjustable (with a minimum spacing of 150mm), and the storage density is 300% higher than traditional shelves, making it suitable for scenarios with limited warehouse space.

- High reliability: low vibration value, high stability, high safety and reliability

- Flexible expansion: Modular architecture supports adding or removing shelf layers and stacking crane quantities as needed

Product parameters

|

Serial Number |

project |

specifications |

|

1 |

Clean Class |

Thousand level |

|

2 |

L·W·H |

2500*1500*2800 |

|

3 |

Traveling speed/acceleration |

2m/s,2m/s² |

|

4 |

Lifting speed/acceleration |

2m/s,1.8/s² |

|

5 |

Fork time |

9s |

|

6 |

Beat (take and put once) |

22.5s |

|

7 |

Electric power |

Normal: 3phase, 380V, 50Hz |

|

8 |

Communication method |

Drag chain or optical communication |

|

9 |

Power supply mode |

Drag chain or sliding contact line |