Don't have an account yet? To register>

Password set successfully

Already have an account? Go to login>

Don't have an account yet? To register>

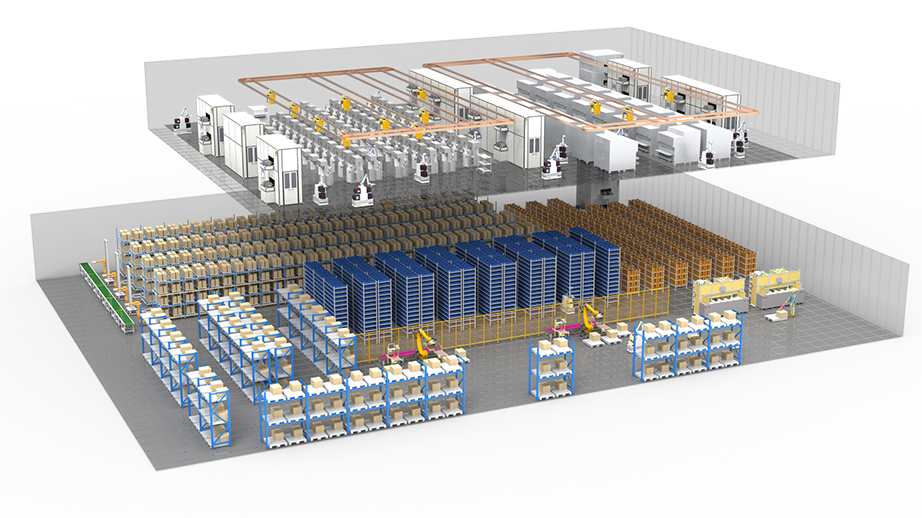

software system

MCS

MCS integrates with equipment (such as automated handling systems, warehousing systems) and upper level systems (such as MES, ERP) to achieve digital management and automated control of the entire process of material receipt and dispatch.

EAP

The EAP system improves production efficiency, reduces manual intervention, optimizes equipment management, reduces costs, and enhances production capacity by automating the control and monitoring of equipment operation.

New machine, supports interfaces, and has original factory services

- Connected to RTD System, directly through RTD

- System interface feedback data

- Supports SECS/GEM protocol and can provide data feedback through standardized interfaces

- The original factory already has other interfaces

New machine, supports interfaces, and has original factory services

- Connected to RTD System, directly through RTD

- System interface feedback data

- Supports SECS/GEM protocol and can provide data feedback through standardized interfaces

- The original factory already has other interfaces

System advantages

- System advantages in manufacturing industries and fields such as semiconductors and display panels enable remote operation and management of production equipment, reducing personnel entry and exit activities in production lines and workshops

- Standardization of SECS/GEM for all equipment in the field, improving standardization of equipment integration and reducing maintenance costs

- Solve the problem of communication difficulties for old machines, lack of support from original suppliers, and inability to collect machine data

- Independent research and development technology, providing global business deployment support

WMS