Don't have an account yet? To register>

Password set successfully

Already have an account? Go to login>

Don't have an account yet? To register>

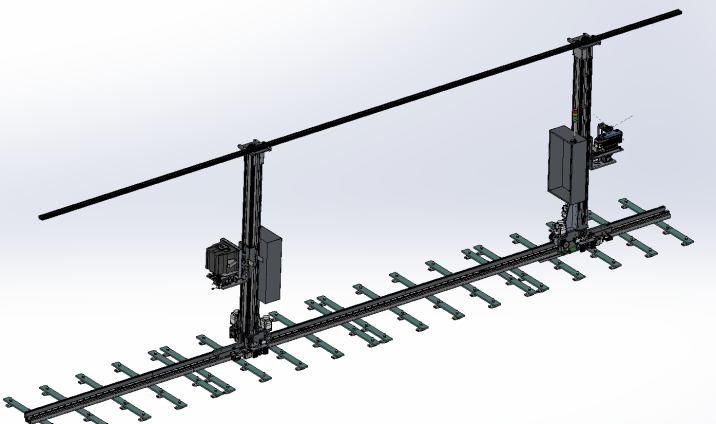

STOCKER

STOCKER is used for the transfer and storage of wafer carriers between production processes in semiconductor cleanrooms. It supports efficient storage and retrieval of SEMI standard carriers such as FOUP, Cassette, Magazine and Tray, etc.; achieves AMR and OHT docking; is compatible with manual loading and unloading; strictly complies with the specifications of FED-209E and SEMI E88 (Stocker SEM); meets the strict requirements of high-cleanliness environment, high throughput efficiency and intelligent management.

Related products

IAR has integrated operational capabilities for movement, grasping and handling. It features high precision, high flexibility, high proliferation, easy operation and human-machine collaboration. It can support rapid integration and implementation in different application scenarios, simplify complex material handling scenarios and achieve more efficient industrial automation.

Technical highlights

- Modular design: The modularization of stacker crane grippers and other components shortens the delivery time and enables rapid delivery

- Short cycle time: High speed of stacker crane and gripper

- Safety and stability: Guarantee the safety of materials and personnel through multiple anti-drop measures and PLC power-off brake

- High scalability: Supports the installation of N2/CDA purification functions and is compatible with the automatic connection with OHT, AGV, IAR and OHCV.

Equipment specifications and parameters

|

Name |

STOCKER |

|

|

Payload |

20kg |

|

|

Carrier Type |

FOUP, CASSETTE, Magazine, Tray |

|

|

Size/Storage Capacity |

Customizable (2.1 * 8 * 2.8m prototype) |

|

|

Input/Output Docking |

AGV/OHT/Manual |

|

|

Pick-and-place Accuracy |

±0.5mm |

|

|

Moving |

speed |

2m/s |

|

acceleration |

2m/s² |

|

|

Lifting |

speed |

1.8m/s |

|

acceleration |

2m/s² |

|

|

Cleanliness Level |

ISO Class 100, Class 1000 |

|

|

Optional |

N ₂ sealing function* |

|

|

Sorter function |

||

stacker

Lifting speed:2m/s; Motor power: 2kw

Moving speed:2m/s; Motor power: 1.5KW;

Fork telescopic speed: 0.75m/s; Rotation time: 1s;

FOUP fork extension motor power: 750W;

MGZ fork extension motor power: 400W;

Walking Barcode positioning: accuracy ± 0.5mm