Don't have an account yet? To register>

Password set successfully

Already have an account? Go to login>

Don't have an account yet? To register>

Application Scenarios

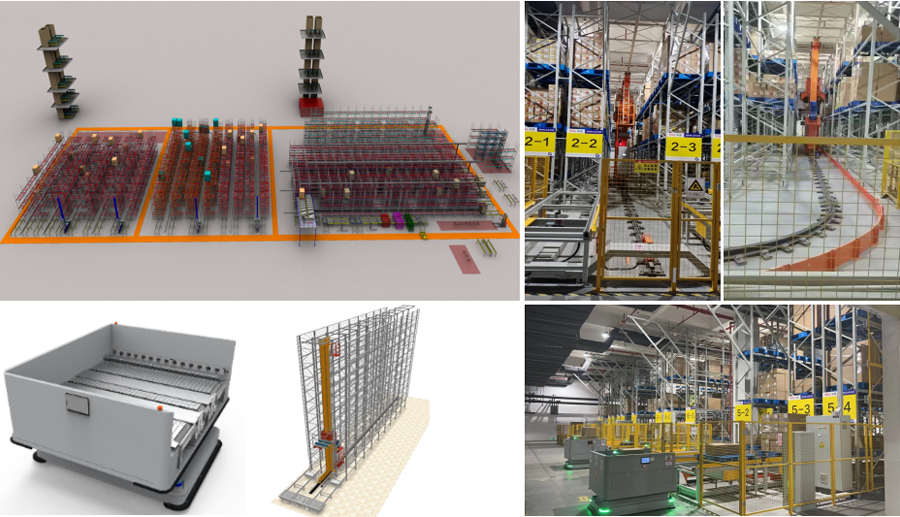

General scenario warehousing and logistics solution

Applied to the raw material/finished product warehouse of LCD panel module section, in order to further promote the construction of intelligent factories, reduce personnel input, improve warehouse storage capacity, enhance logistics reliability and accuracy, investment is made in the construction of intelligent three-dimensional warehouses, and collaborative automated logistics equipment and information management systems are used to meet the production needs of the entire factory.

Project Information:

- Goods unit: L1200 * W1200 * H1600 Goods unit weight ≤ 1000kg;

- Warehouse area: 5000 square meters Number of cargo spaces: 3000;

- Main equipment configuration: stacker cranes (7 units), elevators, conveyors, packaging lines AGV;

- Project value: Achieving automatic storage of raw materials, semi-finished products, and finished product pallets, increasing storage capacity per unit area, improving factory production efficiency, and reducing labor costs.

project introduction

The company focuses on IT services, cloud computing, mobile Internet, big data processing and other industries, and its core business covers hardware, software, and technical services. A new factory will be built as a storage chip production base, and the customer hopes to achieve full process automation of SMT production line cutting and edge storage through intelligent logistics.

- Date of signingOctober 2020

- Implementation locationChongqing City

- Number of AGVs36 units

Customer value.

- Improve logistics efficiency by 40% and significantly reduce logistics delivery error rates

- 50% increase in venue utilization rate

- Reduce manpower by 50%.